A great deal of work has been done to allow an option for a single larger plate instead of multiple smaller plates at the heel and on sliders. Changes include:

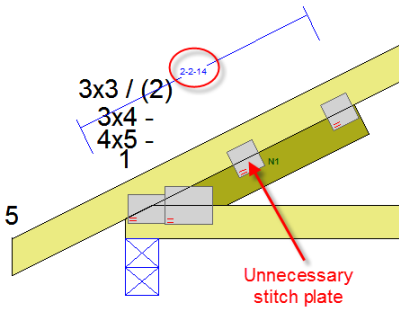

Slider stitch plates are no longer forced if the distance between the shear plate and slider stitch plate at the extent of the slider is less than the 30” slider stitch plate on center spacing.

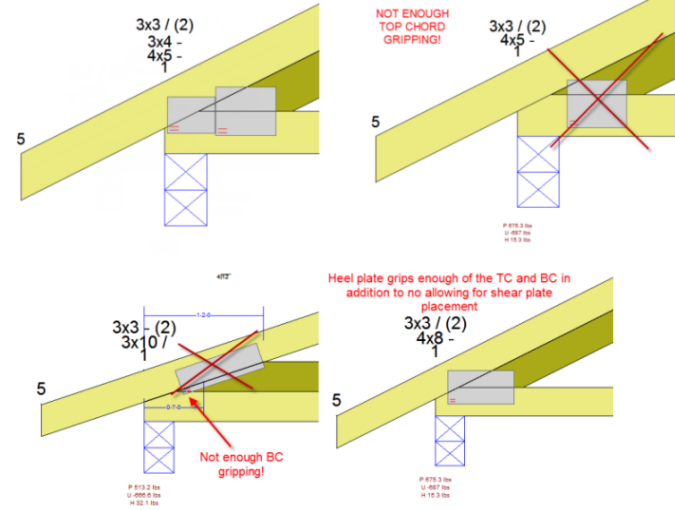

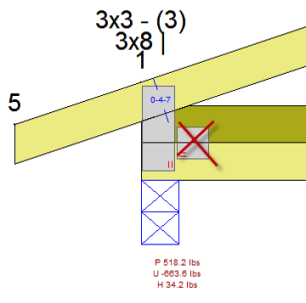

The shear plate has been eliminated in cases where the heel plate gripping area on the chord is greater than or equal to the shear plate’s gripping area on the chord AND the heel plate overlaps the boundary of the shear plate.

The heel “slider tie plate” has been eliminated in cases where the heel plate gripping area on the bottom chord is greater than or equal to the tie plate’s gripping area on the bottom chord.

Automatic optimization of heels with a Slider or Wedge:

KeyTruss® will first select the heel plate based on the current method. If there is no “tie plate” or “shear plate” at the heel, it will accept this as the solution. If there is a “tie plate” or a “shear plate”, the sum of the “heel plate” and “tie plate” or “shear plate” areas will be recorded and compared.

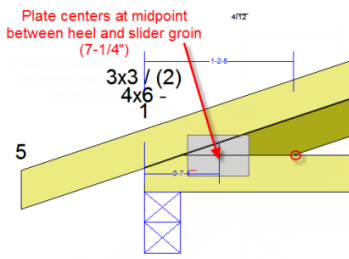

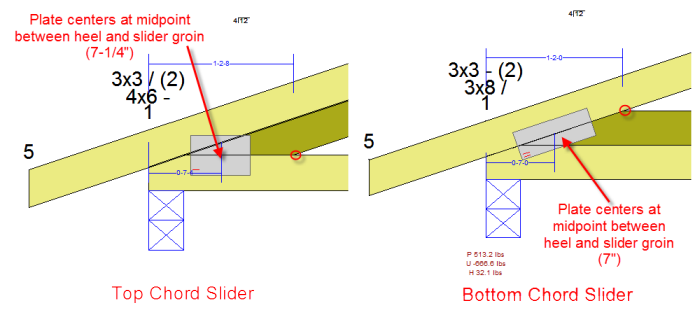

Plate placement during comparison

Horizontal placement:

For wedges, plates will always center on the midpoint between the heel of the truss and the extent of the wedge.

For Sliders, plates will always center on the midpoint between the heel of the truss and the “groin” where the slider first intersects the chord.

Alignment:

When there is no chord gap (CURRENT FUNCTIONALITY):

1. For wedges and TC sliders, the center of the plate will now be aligned with the top edge of the bottom chord.

2. For BC sliders, the center of the plate will now be aligned with the bottom edge of the top chord.

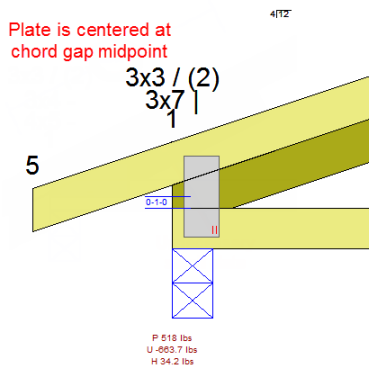

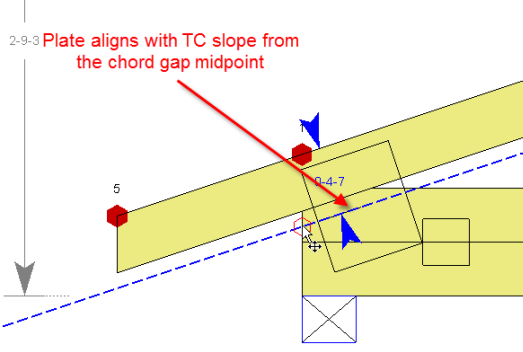

When there is a chord gap at the heel:

1. For all TC slider heel plate orientations and BC sliders with their heel plate vertically oriented, the center of the plate will be vertically aligned with the midpoint of the chord gap.

2. For BC sliders with their heel plate oriented along the TC, the center of the plate will be aligned with the TC slope projection from the midpoint of the chord gap.

KeyTruss® will automatically bump the heel plate size until either the “tie plate” or the “shear plate” is eliminated OR the list of truss plates is exhausted. If one of the plates can be elminated, KeyTruss will compare the plate area of the selected single plate solution to the plate area of the multi-plate solution using the “Max. single plate percentage” value in the Settings (see below). If the list of trusses is exhausted or the single plate's area ends up being larger, KeyTruss will revert to the previous multi-plate solution.

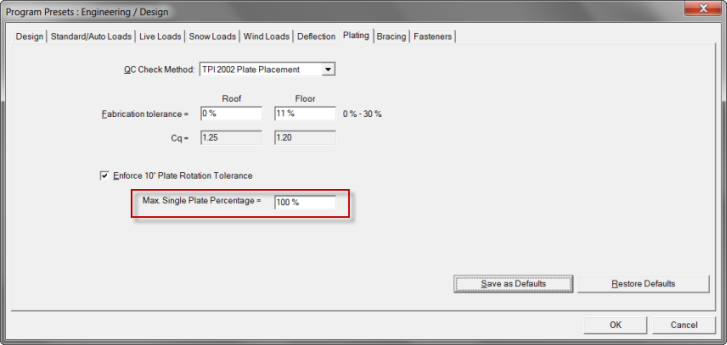

New Setting

As part of this enhancement, the QC tab under Presets | Engineering/Design has been renamed to Plating and a new "Max. Single Plate Percentage" field was added to this tab. The max single plate percentage is the percentage of multiple plate area a single plate’s area must be within for a single plate to be used at a reinforced heel. If the plate area for the single plate solution is less than or equal to the max single plate percentage, then the single plate solution will be used. If the plate area for the single plate solution is greater than the max single plate percentage, the program will revert to the previous multi-plate solution.Note that this comparison is based on area of the plates. Note that, for simplicity, the cost per unit area is ignored thus the comparison is not perfect when different plate gauges or types are mixed. Although not perfect, this is considered acceptable. You can still use the plate editor to manually select the heel plate and the resulting additional plates for this multi-plated condition.